Monthly Archives: July 2013

Sneaky Peek at Autumn/Winter

Whilst we were at the Koziol factory learning about the process of making products we also got to see the products that are to be launched later this year, we thought we’d share our pics with you – what’s the point in seeing something new if we can’t talk about it!

Enjoy the preview and look out for them early September.

Visit To The Happiness Factory Part 2

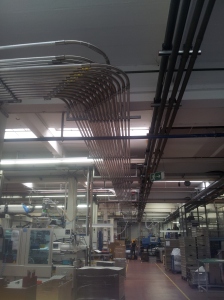

So after the museum, we continued the tour by visiting the factory where we saw products being made by the latest injection mould machines. It takes only 6 seconds to make a Pottichelli pot, the plastic in the form of small beads travels through pipes on the ceiling where it is deposited into the machine, heated to the exact temperature then poured into the injection mould, six seconds later a perfect Pottichelli appears!

Each colour requires an adjustment to the temperatures settings, for instance purple isn’t heated to the same temperatures as say black or yellow. All the products are carefully inspected by an eagle-eyed member of staff and any colour variations or imperfect products are sent off to the recycling bin.

We then were shown shelf after shelf of injection moulds, some of which are made in the factory then if needed they are hand polished to give a shiny glossy finish on the product. The moulds are a huge investment as they cost hundreds of thousands of pounds to make, so need to be taken care of, they can last well over 100 years.

We did actually see an injection mould being made. A small piece of metal in a glass box was being repeatedly bombarded by water jets to soften the edges and create a rounded surface; meanwhile on the other side of the factory floor a square sharp-edged mould was being made by an electrical spark, this one we couldn’t get too close too for obvious reasons!

Finally the tour ended in a photography studio where we were given a sneak preview of some of the fabulous new products, watch this space…..